The Rise of Robotic Lawn Mowers: Mammotion LUBA 2

Robot lawnmowers have also grown in popularity thanks to their efficiency and convenience. With the progress in technology, these automated lawn maintenance solutions are being used by homeowners and commercial entities. Mowers available for this purpose are of course automatic lawn mowers, used to automatically mow lawns without the need for manual effort.

Mammotion LUBA 2 is unique in its suitability for a variety of lawn care tasks. With precision navigation systems, it mows the yard in precise lines further minimizing human interaction. With its rugged design, it can handle various terrains, making it appropriate for various environments. In addition, the energy-efficient design and intuitive operation are helping it gain traction among tech-savvy consumers.

Common Challenges Faced by Robotic Lawn Mowers

Harsh Working Environments

They do their cutting inside as the name suggests but outdoor conditions like dirt, water, plants, debris, and chemicals around it. These particles can damage the internal also of the machine. It is thus essential that these devices are protected against such extreme environmental conditions. It is essential that these devices maintain protection against extreme environments.

Precision Requirements in Operation

Precision is paramount for robotic lawn mowers as they must navigate complex landscapes with accuracy. Any deviation can lead to incomplete mowing or damage to the mower itself. Hence, maintaining precise movements is essential for optimal performance.

Long-term Durability Needs

But a big worry many with robotic lawn mowers have is durability. Such machines need to be able to withstand prolonged and continual use without too much wear and tear. Materials and parts that can endure several environmental inquiries, which is really essential for durability. To stay in the game for the long term, it needs parts that can stand up to the regular punishment of environmental stressors.

How Silicone Parts Assist Robotic Lawn Mowers

Silicone Seals to Resist Environmental Intrusion

Protection Against Dust and Moisture

Silicone seals work best to keep dust and moisture out of the inner part of the machine. They act as a barrier method from all of these elements, helping to ultimately define the life span of the sensitive components and help the overall life of the mower.

Enhancing Lifespan of Components

Silicone parts also help to considerably lengthen the lifetime of individual components in a robotic lawn mower. The inherent durability of silicone makes sure seals do not fail, providing continuous protection even when facing constant exposure to adverse conditions.

![]()

Silicone Cushions for Internal Protection

Vibration Dampening Benefits

Robotic lawn mowers often face vibrations during operation due to uneven terrain and mechanical movements. Silicone cushions serve as an effective solution by dampening these vibrations, minimizing potential damage to internal parts.

Impact Resistance Features

Apart from vibration dampening they also have a high impact-resistance advantage over metals. This is an essential feature because sensitive parts can experience an unexpected harsh glass or impact on the mowing track.

![]()

Precision Silicone Components for Smooth Operation

Ensuring Accurate Movements

Silicone parts are instrumental in ensuring precise movements within robotic lawn mowers. Their flexibility allows for smooth articulation of moving parts, resulting in accurate navigation across varied landscapes.

Reducing Mechanical Wear and Tear

By facilitating seamless operation, silicone components help reduce mechanical wear and tear on the mower’s moving parts. This reduction not only enhances performance but also contributes to longer service life.

![]()

Fire-Resistant Properties to Lower Combustion Risks

Thermal Stability Advantages

Silicone’s fire-resistant properties provide significant thermal stability advantages for robotic lawn mowers operating under high temperatures or near flammable materials. Incorporating fire-resistant silicone into mower design enhances safety by lowering combustion risks associated with overheating or accidental ignition during operation.

Easy Maintenance and Cleaning

Maintenance and cleaning are less complicated with silicone components due to the minimum stickiness and resistance to chemical deterioration. Such require less user effort to keep robotic lawn mowers functional. The convenience in maintenance will help keep robotic mowers in individual use with the lowest efforts needed from their owner.

Silicone parts are designed by robotic lawn mowers such as the Mammotion LUBA 2, which not only protects them from challenging environments but also maintains the precision and durability needed for efficient operation on different surfaces.

CASINDA High-Quality Custom Silicone Parts for Robotic Lawn Mowers

High Precision Shape Customization

CASINDA provides high-precision shape silicone parts customization for robotic lawn mowers. Such a detailed level of customization is critical because it facilitates the fabrication of components that fit the unique design and operational needs of each mower model. With the enhanced manufacturing process, CASINDA provides every silicone part that has fulfilled the specifications required to ensure that they offers optimal performance and durability.

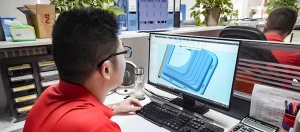

Expertise in Manufacturing Technology

CASINDA professionals have above-level experience with manufacturing technology to allow robotic silicone parts to achieve higher quality and consistency. CASINDA uses the most advanced equipment and processes, including rubber injection molding to manufacture components with very high durability and reliability. This advanced technology makes sure that the silicon parts resist the operational stress which robotic lawnmowers are exposed to.

Rigorous Quality Testing Procedures

CASINDA performs strict quality testing policies on every silicone part to ensure its quality and durability. This includes material property validation, consisting of tests for tensile strength, thermal endurance, and environmental durability. Through extensive assessments, CASINDA certifies that its silicone parts work well under different forces, raising the entire effectiveness level and durability of robotic lawn mowers.

Exploring More Silicone Product Offerings

Having not only manufactured custom parts for robotic lawn mowers and paved the way to become a comprehensive silicone solution provider, CASINDA is still looking for potential silicone product lines to accommodate this ever-expanding sector. Through this commitment to innovation, CASINDA can diversify its product line and provide solutions to new problems found in the fields of robotics and automation. Through this commitment to innovation, CASINDA can continuously broaden its product portfolio by including solutions for new challenges facing robotics and automation.

Integrating CASINDA high-quality custom silicone parts provides robotic lawn mower manufacturers with excellent protection against environmental challenges while maintaining the precision and durability needed to operate efficiently in different terrains. Manufacturers of robotic lawn mowers can capture the same benefits of performance while simultaneously optimizing protection against environmental challenges by integrating high-quality custom silicone parts from CASINDA with precise, durable features to keep up with their effective operation across many varied terrains.

FAQs About Robotic Silicone Parts

Can Silicone Be Exposed to Water?

Due to being waterproof, silicone is also a very frequent material of choice in outdoor applications for robotic lawn mowers. Also, it is non-porous, which means that it does not absorb water, protecting internal parts of the equipment from moisture damage. The feature guarantees silicone seals get the job done best even though the maxim moist conditions are often experienced in mowing.

Is Silicone Conductive?

Second, Silicone does not conduct electricity, so robots can use silicone in fields that require electrical insulation. With heat insulation properties of PMMA help prevent short circuits and electrical failures in robotic systems and increase the operation safety and reliability. This insulating characteristic avoids shorts as well as the electrical malfunctioning of robotic systems, increasing operational safety and reliability.

How to Clean Silicone Components in Robots?

Silicone used in the robots is non-stick, so cleaning the silicone components is easy. Using a solution of mild detergent and a cloth or sponge, wipe dirt or debris from the exterior of these areas. Do not use any hard chemicals or scrub any hard material that can harm the silicone surface. Silicone parts can stay in good condition through regular maintenance to ensure both performance and appearance over time.