Understanding Silicone Molds and Their Versatility in OEM/ODM

Introduction to Silicone Molds

Silicone molds have transformed how different industries handle manufacturing. Silicone is ideal for mold fabrication due to its strength, versatility, and inert properties, making it essential for producing various products. This enables detailed designs and accuracy in the molding process, rendering silicone molds vital in contemporary manufacturing.

Importance of Customization in OEM/ODM Processes

Customization is a cornerstone of OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) processes. Companies often require specific designs and functionalities to meet their unique needs, and silicone molds are ideal for this purpose. They can be tailored to create custom parts and products, ensuring that businesses can innovate without being confined to standard designs. The flexibility of silicone molds makes them perfect for short-run productions or complex product designs that require a high degree of customization.

Benefits of Using Silicone for Custom Molding

Silicone offers a multitude of benefits when used in custom molding for OEM/ODM. Firstly, its thermal stability and resistance to a wide range of chemicals make it suitable for various applications. Secondly, silicone molds provide exceptional detail replication, which is crucial for products that need precise specifications. Furthermore, silicone molds are reusable and durable, reducing overall production costs and waste. These advantages underscore the significance of silicone in custom molding activities for OEM and ODM processes.

Exploring the Role of Silicone Molds in OEM/ODM Production

Advantages in the Manufacturing Process

Silicone molds bring a multitude of advantages to the manufacturing process. One of the key benefits is their ability to create complex geometries that would be challenging to achieve with traditional manufacturing techniques. This capability allows for innovative product designs and improvements in functionality. Additionally, silicone molds can withstand high temperatures and pressures, making them suitable for a variety of production environments. These properties make silicone molds a vital component in the manufacturing toolkit for OEM/ODM.

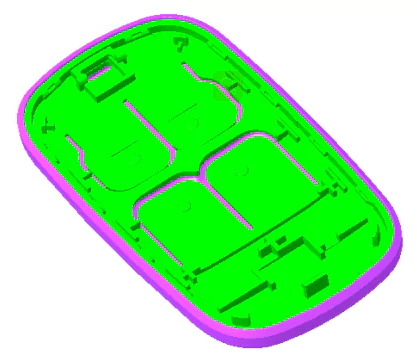

![]()

Quality Control and Precision

In OEM and ODM production, quality control and precision hold significant importance. Silicone molds are particularly effective in upholding high-quality standards due to their capability to accurately replicate intricate details. This precision guarantees that each product adheres to the strict requirements established by the manufacturer, thereby minimizing defects and rework. Additionally, the reliable performance of silicone molds helps maintain uniformity across all produced items, which is crucial for brand reliability and customer satisfaction.

Cost-Effectiveness and Scalability

Silicone molds offer significant cost-effectiveness and scalability benefits in OEM and ODM production. The initial investment in creating silicone molds can be offset by their long lifespan and reusability, leading to lower production costs over time. Additionally, silicone molds are well-suited for both small batch productions and large-scale manufacturing, allowing companies to scale their operations based on demand. This adaptability ensures that businesses can remain competitive without incurring excessive expenses, making silicone molds a smart choice for OEM/ODM production.

In conclusion, the hidden possibilities of silicone molds in silicone product OEM/ODM are vast and varied. From enabling high levels of customization to ensuring cost-effectiveness and scalability, silicone molds play a crucial role in modern manufacturing processes. Their ability to deliver high-quality, precise, and durable products makes them an invaluable asset for any company engaged in OEM or ODM activities. As industries continue to evolve, the reliance on silicone molds is expected to grow, further highlighting their importance in the production landscape.

Customization Capabilities of CASINDA

Tailored Design Solutions for Clients

In the realm of silicone product OEM/ODM, CASINDA shines with its tailored design solutions for clients. The company prioritizes customer needs and preferences.By leveraging advanced technologies and a team of experienced designers, they can create highly customized silicone molds that meet exact specifications. Personalized approach enhances product functionality and aligns with client’s vision and market requirements.

Prototyping and Development

Creating prototypes is a crucial component of the OEM/ODM workflow, and CASINDA excels in this domain. The company utilizes advanced prototyping methods to create initial models, enabling clients to see and test their designs prior to mass production. This step is essential for spotting any potential issues early on and making the necessary modifications. The capability to rapidly produce and refine prototypes guarantees that the final silicone product OEM/ODM adheres to the highest quality standards and meets all client requirements.

Flexibility in Design Modifications

Flexibility is a key attribute in the silicone molds creation process at CASINDA. The company understands that design needs can evolve, and they offer the ability to make modifications swiftly and efficiently. This adaptability is crucial for accommodating changes in product design, functionality, or even regulatory requirements. Flexibility in design tweaking ensures product competitiveness.

Advanced Production Techniques and Technology Integration

CASINDA integrates advanced production techniques and cutting-edge technology into its manufacturing processes. This integration enhances the efficiency and quality of silicone molds production, resulting in superior silicone product OEM/ODM services.

Innovative Mold-Making Equipment

The use of innovative mold-making equipment is a hallmark of CASINDA’s production process. The company invests in the latest machinery and tools to create high-precision molds that can produce detailed and intricate parts. These advanced equipment capabilities allow for the production of complex geometries and fine details that are critical in many silicon product applications. The innovation in mold-making equipment also ensures higher production speed and consistency, which are essential for meeting tight deadlines and maintaining product quality.

Automation and Efficiency

Automation is crucial for enhancing production efficiency at CASINDA. By integrating automated systems into the manufacturing process, the company can sustain high efficiency levels and minimize human error. This automation ensures the consistent production of high-quality silicone molds, which helps the company to meet the growing demands for silicone product OEM/ODM. The increased efficiency leads to cost savings, quicker turnaround times, and overall improved productivity.

Industry Applications of Silicone Molds

Consumer Goods and Household Items

Silicone molds find extensive use in the production of consumer goods and household items. Their ability to create flexible, durable, and non-toxic products makes them ideal for manufacturing kitchenware, bakeware, and other everyday items. The precision and detail that silicone molds offer ensure that each product is both functional and aesthetically pleasing. Additionally, the non-stick properties of silicone make it a preferred choice for items that come in contact with food, such as O-Sealing ring, providing safe and easy-to-clean options for consumers.

Medical and Healthcare Products

In the medical and healthcare sector, silicone molds are crucial for creating products that meet stringent safety and quality standards. Their biocompatibility and hypoallergenic properties make silicone an ideal material for medical devices, implants, and prosthetics. The customization capabilities of silicone product OEM/ODM enable the production of bespoke medical solutions tailored to individual patient needs. Additionally, the ability of silicone to withstand sterilization processes without degrading ensures that medical products remain safe and effective throughout their use. For example, LSR is mainly used for children’s products and medical supplies relying on Excellent tear strength, resilience and thermal stability.

Electronics and Technology Accessories

Silicone molds are also widely used in the electronics and technology industry for manufacturing various accessories and components. The material’s insulation makes it suitable for electronic device casings, seals, and gaskets. Furthermore, the flexibility of SIL allows for the production of ergonomic and durable accessories such as phone cases, keyboard covers, and wearable tech components. The precision offered by silicone molds ensures that each accessory fits perfectly and performs reliably, which is critical in the highly competitive tech market.

The concealed potential of silicone molds in silicone product OEM/ODM keeps expanding as various sectors uncover fresh uses and advantages. The ability to customize, paired with cutting-edge production methods and the extensive range of industry applications, positions silicone molds as a vital asset in contemporary manufacturing. With technological progress and shifting market needs, the importance of silicone molds is poised to grow further, playing a crucial role in producing innovative and top-quality products.

Ensuring High Standards: The Promise of CASINDA

Commitment to Quality Assurance

Material Testing and Compliance

CASINDA is dedicated to maintaining the highest standards of quality in their production processes. One of the fundamental aspects of this commitment is rigorous material testing and compliance. Every silicone mold used in the manufacturing process undergoes thorough testing to ensure it meets industry and regulatory standards. This includes assessments for durability, flexibility, and resilience to various chemicals and temperatures. Compliance with international standards not only guarantees product safety but also enhances customer trust and satisfaction.

Customer Feedback Mechanisms

Understanding the needs and experiences of customers is crucial to improving and maintaining quality. CASINDA implements a robust customer feedback mechanism to gather insights on their silicone product OEM/ODM services. This system allows clients to provide detailed feedback on product performance, design, and functionality. The company uses this valuable information to make iterative improvements and address any concerns promptly. By fostering open communication with their customers, the company ensures continuous enhancement of their products and services.

Continuous Innovation and Improvement

Research & Development Initiatives

Innovation is at the heart of CASINDA’s success. The company invests significantly in research and development initiatives to push the boundaries of silicone molds technology. Their dedicated R&D team works on developing new materials, refining production techniques, and creating innovative designs that meet evolving market demands. These initiatives enable the company to stay ahead of industry trends and offer cutting-edge solutions to their clients, ensuring that their silicone product OEM/ODM services remain competitive and relevant.

Technological innovation drives business

CASINDA plays a crucial role in its OEM/ODM silicone product business through its strong technical team, mold equipment, and measurement instruments. The company’s technological innovation and dedicated technical team enable them to develop and manufacture high-quality silicone products. Additionally, their advanced mold equipment ensures efficient production and precise product manufacturing. The presence of accurate measurement instruments further guarantees the quality and consistency of their silicone products. Overall, the combination of a skilled technical team, state-of-the-art mold equipment, and reliable measurement instruments greatly contributes to the success of their OEM/ODM silicone product business.

How to Engage with CASINDA for Your OEM/ODM Needs

Initial Consultation and Requirements Gathering

Engaging with CASINDA for your silicone product OEM/ODM needs starts with an initial consultation and requirements gathering. During this phase, their experienced team works closely with clients to understand project objectives, design specifications, and desired outcomes. Detailed discussions help clarify technical requirements, potential challenges, and expected timelines. This comprehensive approach ensures that all client needs are thoroughly understood and addressed, setting the foundation for a successful collaboration.

Quotation, Agreement, and Project Kickoff

Following the initial consultation, CASINDA provides a detailed quotation that outlines the costs and scope of the project. This transparency allows clients to make informed decisions and plan their budgets effectively. Once the quotation is approved, a formal agreement is signed, and the project moves into the kickoff phase. During this stage, the project teams are assembled, timelines are finalized, and initial production activities begin.

Monitoring Progress and Final Delivery

Throughout the production process, CASINDA places a strong emphasis on monitoring progress to ensure that all project milestones are met. Regular updates and reviews are conducted to track the development of silicone molds and ensure compliance with client specifications. Any issues or delays are promptly addressed to maintain project schedules. Upon completion, the final products undergo rigorous quality checks before delivery. This meticulous approach guarantees that the final silicone product OEM/ODM meets the highest standards and exceeds client expectations.

By maintaining rigorous quality benchmarks, fostering ongoing innovation, and providing thorough engagement procedures, CASINDA distinguishes itself as a dependable collaborator in the realm of silicone molds and silicone product OEM/ODM. Their dedication to excellence guarantees that clients obtain products that are both top-notch and customized to their unique requirements, promoting success and contentment in their individual markets.